New Volkswagen engine

cars of the legend for car enthusiasts, concept cars, super cars, collections and much more on cars of the legend.

New Volkswagen engine for Volkswagen's all-electric range

New Volkswagen engine for Volkswagen’s fully electric range: improved performance and increased efficiency of ID models.

Noticeable increase in power and torque

Increased autonomy for ID models.

Volkswagen intends to introduce the new engine from the fourth quarter of 2023

Production at the Volkswagen Group Components site in Kassel (Germany)

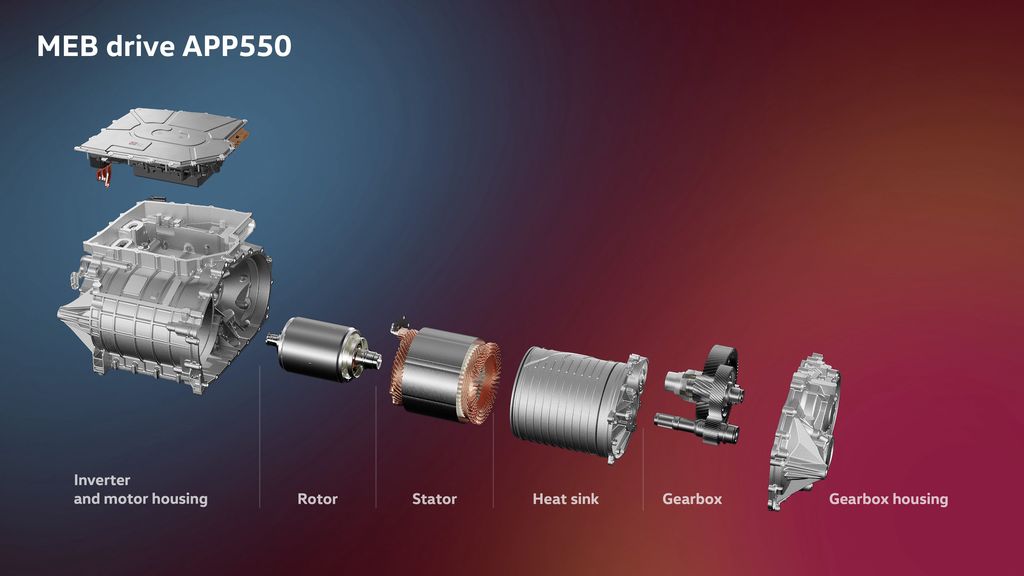

Volkswagen recently announced the upcoming release of the next generation of new Volkswagen engines for the ID range models. The ID range. is equipped with a new rear motor called APP550 which will offer optimized performance and better energy efficiency for Volkswagen’s 100% electric vehicles. The models in the ID range. will be equipped with this new technology which will give them more power and improved autonomy. The first models equipped with the 210 kW (286 hp) version of this engine will be available at the end of the year.

The new electric motor developed by Volkswagen is based on the Modular Electric Platform (MEB) specially designed for the production of electric vehicles. The Head of Powertrains and Energy Systems within the Technical Development Department, Karsten Bennewitz, explained that despite the limited space to install the powertrain, the team managed to develop a new engine capable of offering increased performance and efficiency while meeting the same physical size constraints. This challenge was met by the Technical Development Department of the Group Components division, which managed to significantly improve the efficiency of the vehicle while reducing the use of raw materials.

More power, significantly increased torque with the new Volkswagen engine

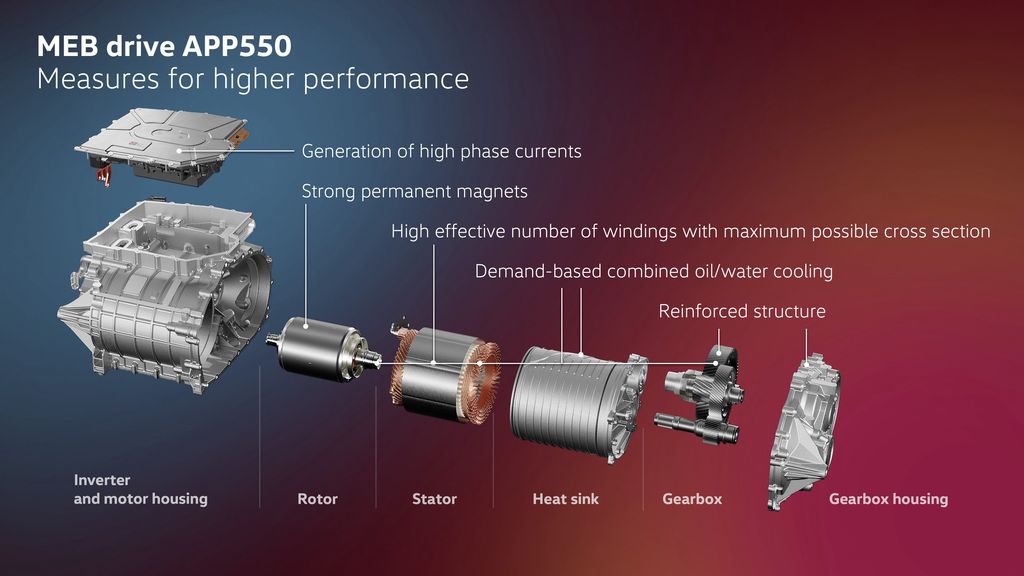

Volkswagen’s new powertrain, the APP550 electric motor, produces an output of 210 kW (286 hp) and a maximum torque of almost 550 Nm, depending on the vehicle’s transmission ratio. The significant increase in torque allows for remarkable acceleration capability, whether from a standing start or at high speeds. This performance is made possible thanks to an optimized stator, which has a large number of efficient windings and a larger wire section. Additionally, the rotor is equipped with a stronger permanent magnet, with increased magnetic capacity. The new engine has been designed to withstand the higher torques generated, enabling a significant improvement in vehicle performance.

Pulse width modulated inverter for high currents

In an electric motor, the intensity of the electric current is a crucial factor in determining the power. So, Volkswagen developed the Pulse Width Modulated (PWM) inverter to provide high phase currents, which helps increase engine power and efficiency. The MLI inverter is considered the “brains” of the powertrain and its functional software ensures the efficiency of processes in the system. This process optimization is applied to clock frequencies and modulation processes for the generation of alternating current for the electric motor, thus enabling more efficient use of energy depending on the charging phase.

Optimized thermal management thanks to an intelligent cooling system

Volkswagen has optimized several powertrain components to increase the efficiency of the new electric motor. The thermal management system has been particularly improved. The engine is equipped with an energy-saving cooling system that operates without an electrically controlled oil pump. This system can cool itself thanks to the mechanical transmission gears and specially designed components to ensure oil distribution. The heated oil is then cooled by the vehicle’s cooling system, thus keeping the engine at optimal operating temperature. Additionally, the exterior of the stator is equipped with a water cooling jacket (jacket). This optimization of the thermal management system contributes greatly to the overall efficiency of the electric motor.

Volkswagen site in Kassel: production center for electric powertrains

The new Volkswagen engine with transmission, rotor and stator are manufactured at the Volkswagen Group Components site in Kassel. Director of Technical Development Electric Motors, Power Electronics & Transmission at Group Components, Alexander Krick, said that the company has been developing electric motors and transmissions for more than 15 years and has been producing these technical components at the Kassel site since. more than 10 years. Innovations in electric motors and mechanical transmissions, as well as advances in production processes, have greatly contributed to improving the efficiency and performance of electric cars. Alexander Krick emphasized that the use of special magnetic sheets and the implementation of optimized machining processes have made it possible to significantly increase the efficiency of electric motors thanks to their experience gained over the years in this area.